Email: cbeswick@allsafesolutions.co.uk

Mobile: 07788 371796

Email: cbeswick@allsafesolutions.co.uk

Mobile: 07788 371796

Email: cbeswick@allsafesolutions.co.uk

Mobile: 07788 371796

Email: cbeswick@allsafesolutions.co.uk

Mobile: 07788 371796

AllSafe Solutions Ltd is a family run business with over 20 years’ experience within the Working at Height industry. We specialise in rope access, maintenance, cleaning, pest control and testing of safety equipment.

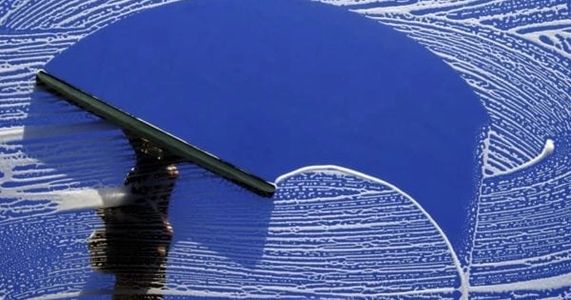

The traditional method is done with the window cleaner applying a cleaning solution to the window with an applicator, then cleaning it off manually with the use of a squeegee. We then wipe down the window sill and edges with a clean cloth leaving a perfectly clean window every time. We use this method for all our internal cleaning works as the windows are a lot more accessible and a perfect cleaning finish is usually always guaranteed.

Reach & Wash allows windows to be cleaned from the safety of the ground using long reaching, telescopic poles. A soft bristled brush is used to scrub the dirt off of the glass, while jets of pure water rinse the window. The pure water, (as it has no impurities) dries to a spot-free finish leaving no marks behind.

We believe that keeping an office environment clean and hygienic is essential. This stretches from surface and desk cleaning to carpet and floor cleaning. We hav high-quality equipment to deliver a full office cleaning service and to give you peace of mind. Each company has their individual requirements, which is why our highly efficient office cleaning staff are capable of maintaining the cleanliness of your business.

Rope access is a safe method of working at height where ropes and associated equipment are used to gain access to and from the work position, and to be supported there. The advantage of using rope access methods lies in the safety and speed with which workers can get to or from difficult locations in order to carry out their work, often with minimal impact on other operations, surrounding areas and the environment. The primary objective when using rope access methods is to carry out the work efficiently, with minimal accidents, incidents or dangerous occurrences. In order to ensure a safe system of work is maintained at all times, whilst avoiding damage to property or harm to the environment, careful planning and documented risk assessments are undertaken for each operation.

Our engineers take great pride and care in the inspections they complete to ensure original installation guidelines are followed.

Eyebolt Anchors should be inspected and tested at least every 12 months as per the lifting operations and lifting equipment regulations 1998, (LOLER).

This would consist of, (but not limited to) the following:

• Examination of the eyebolt for correct marking

• Surrounding structure inspected for damage or cracks

• Check, as far as possible, that positioning requirements are met.

• Anchor device can be accessed before the user is at risk

• Physical examination where applicable

• Up-dating of signage as applicable

Following a successful test, a full report detailing our findings would be issued along with certificates for each individual asset.

Abseil Eyebolt Inspections

Abseil Anchors should be inspected and tested at least every 6 months as per the lifting operations and lifting equipment regulations 1998, (LOLER).

Mansafe Systems are horizontal safety lines designed to keep people safe whilst working at a height. Mansafe systems can be designed for restraint purposes, (to prevent a fall occurring) but must be able to take fall arrest loading in accordance with EN795 and the equipment being misused.

A mansafe fall protection system can be designed as either fall restraint; the system is installed typically no less than 2m from the fall hazard. All types of fall arrest systems and fall restraint systems still need to be tested and inspected regularly to check for any faults and to ensure that the system is fit for purpose. In accordance with EN795 and manufacturers guidance, these should be inspected and tested at least every 12 months and that an independent risk assessment should be undertaken to determine if a more frequent visit is required.

Collective protection systems such as handrail, guardrail, balustrade and barriers are an essential choice when considering fall protection. Within the workplace these items are classed as work equipment.

The Provision and Use of Work Equipment Regulations (P.U.W.E.R) 1998 require the “Duty Holder” to ensure that any work equipment provided is;

It is therefore essential to have your Collective Protection Systems inspected on a regular basis, by a competent company, such as AllSafe Solutions. These inspections provide peace of mind and help to reduce the risks to workers. It is recommended that collective protection should be tested and inspected at frequencies not exceeding 12 months.

Our technicians clean all types of public and private areas, both indoors and out.

Examples of cleaning projects that we carry out:

Our experts use hot jet washing machinery and specialist chemicals to clean all types of areas, for both the sake of cosmetic / aesthetic purposes but also for public safety. Untreated areas of spillages can be dangerous to the public and your staff, accidents can lead to hefty insurance and legal claims.

There is an abundance of building maintenance projects which can utilise rope access methods, these include:

Installation of:

This is just a small indication of how the use of rope access techniques can benefit building maintenance.. No matter how challenging or complex a project may appear to be, we are always looking to apply our expertise to a new and exciting project..

We offer a full range of high-level gutter cleaning services for commercial clients and businesses throughout the UK. Keeping your gutters clear is one of the best ways to comply with insurance policies, ensuring that if your roof line develops a leak, your insurers will pay out.

Gutters form a vital part of your building’s weatherproofing and as such, they need to be kept clear so they can function correctly. We have nearly two decades of experience in the industry and can provide you with a cost-effective gutter cleaning service; From schools and colleges to office blocks and retail parks, we are able to undertake all types of high-level gutter cleaning.

The standard netting is black in colour and made from a 12/6 polyethylene knotted twine, manufactured to a net mesh of either 75mm, 50mm, 28mm and 19mm, depending on which species of bird is proving to be most problematic. The nets are attached to a 2mm stainless steel perimeter wire, which is held in place by a variety of stainless steel intermediate fixings. The wire is then tensioned using stainless steel barrel strainers, and the net is then attached using stainless steel hog rings. All the fixtures and fittings are 316 Marine Grade Stainless Steel and are fitted using dome head rivets to prevent water ingress, so you can be confident that they are durable and weather proof, and you can expect them to last for up to 10 years!

The fine, stainless steel pins are fitted to a poly carbonate base. These are then attached using a strong clear silicone adhesive. As no drilling is required there is no damage to the building structures, so the pigeon spike system is ideal for older buildings and has a minimum impact structure. This is quite an intensive bird proofing method, and is ideal if gulls or pigeons roost on your building overnight, but for lighter pressure areas, we have a selection of bird deterrent systems that may be more suitable, including bird netting and bird wire.

We value our customers, so feel free to arrange a visit during normal business hours.